NEW

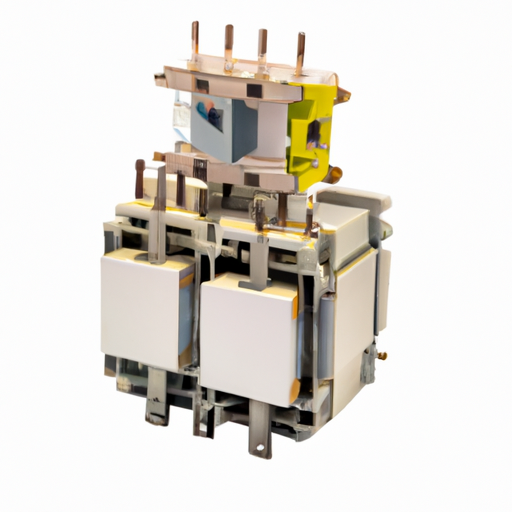

Application Development in Single IGBTs for CFR-25JB-52-1K8: Key Technologies and Success StoriesDeveloping applications using Single Insulated Gate Bipolar Transistors (IGBTs) like the CFR-25JB-52-1K8 requires a comprehensive understanding of the underlying technologies and successful implementations across various sectors. Below is an overview of the key technologies and notable success stories associated with the use of IGBTs.

Key Technologies1. IGBT Technology2. Thermal Management3. Gate Drive Circuits4. Modulation Techniques5. Protection Circuits6. Integration with Digital Control1. Renewable Energy Systems2. Electric Vehicles (EVs)3. Industrial Drives4. HVDC Applications5. Consumer Electronics Success Stories ConclusionThe CFR-25JB-52-1K8 IGBT exemplifies the advancements in IGBT technology, offering efficiency, reliability, and versatility across various applications. By leveraging innovations in gate drive technology, thermal management, and digital control integration, developers can create cutting-edge solutions in sectors such as renewable energy, electric vehicles, industrial automation, and consumer electronics. The success stories highlight the transformative impact of IGBT technology in modern power electronics, paving the way for future advancements and applications.

CFR-25JB-52-1K6 Resonators: Core Functional Technology and Application Development CasesThe CFR-25JB-52-1K6 is a specific type of resonator that exemplifies the critical role resonators play in electronic circuits, particularly in timing and frequency control applications. Below, we delve into the core functional technology of resonators and highlight various application development cases where they are effectively utilized.

Core Functional Technology of Resonators1. Basic Principle2. Types of Resonators3. Key Parameters4. Applications1. Consumer Electronics2. Automotive Systems3. Telecommunications4. Medical Devices5. Industrial Automation6. Internet of Things (IoT) Application Development Cases ConclusionResonators, including the CFR-25JB-52-1K6, are essential components in modern electronics, providing stability and precision across a wide range of applications. Their ability to maintain accurate frequencies makes them indispensable in consumer electronics, automotive systems, telecommunications, medical devices, industrial automation, and IoT applications. As technology continues to evolve, advancements in resonator types and materials will further enhance their performance and expand their application scope, driving innovation in various fields.

Application Development in VCOs (Voltage Controlled Oscillators) for CFR-50JB-52-1K6: Key Technologies and Success StoriesVoltage Controlled Oscillators (VCOs) are essential components in a wide range of applications, particularly in communication systems, signal processing, and frequency synthesis. The CFR-50JB-52-1K6 is a specific model of VCO that exemplifies the advancements in this technology. Below is an overview of key technologies and notable success stories related to the application development of VCOs, with a focus on the CFR-50JB-52-1K6.

Key Technologies in VCO Development1. Phase-Locked Loops (PLLs)2. Integrated Circuit (IC) Design3. Temperature Compensation4. Low Phase Noise Design5. Digital Control Interfaces6. Wide Tuning Range1. Telecommunications2. Satellite Communication3. Test and Measurement Equipment4. Consumer Electronics5. Automotive Applications Success Stories in VCO Applications ConclusionThe development of VCOs, particularly models like the CFR-50JB-52-1K6, has been propelled by technological advancements and the growing demand for reliable frequency generation across various applications. Success stories in telecommunications, satellite communication, test equipment, consumer electronics, and automotive sectors underscore the versatility and significance of VCOs in modern technology. As applications continue to evolve, ongoing innovations in VCO design and integration will be crucial in meeting future demands, ensuring that VCOs remain at the forefront of electronic and communication technologies.

CFR-50JB-52-1R6 Programmable Oscillators: Core Functional Technology and Application Development Overview of Programmable OscillatorsProgrammable oscillators are essential electronic components that generate precise frequency signals, which can be adjusted or programmed to meet specific application requirements. The CFR-50JB-52-1R6 is a notable model that exemplifies the capabilities of programmable oscillators, offering flexibility, accuracy, and reliability across various applications. Core Functional Technology1. Frequency Programmability 2. Low Phase Noise 3. Temperature Stability 4. Low Power Consumption 5. Digital Control Interface 6. Compact Form Factor 1. Telecommunications2. Consumer Electronics3. Industrial Automation4. Medical Devices5. Automotive Systems6. IoT Devices Application Development Cases ConclusionThe CFR-50JB-52-1R6 programmable oscillator represents a significant advancement in frequency generation technology. Its core functionalities, including programmability, low phase noise, and temperature stability, make it suitable for a wide range of applications across various industries. As technology continues to evolve, the role of programmable oscillators will become increasingly important in developing innovative solutions that require precise timing and frequency control, paving the way for advancements in telecommunications, consumer electronics, industrial automation, medical devices, automotive systems, and IoT applications.

Application Development in Switching Converters and SMPS Transformers: CFR-25JB-52-1R5The development of applications utilizing switching converters and SMPS (Switched-Mode Power Supply) transformers, such as the CFR-25JB-52-1R5, is a dynamic field characterized by rapid technological advancements and diverse application areas. Below, we delve deeper into the key technologies and notable success stories that illustrate the impact of these innovations.

Key Technologies1. Magnetic Design2. Control Techniques3. Thermal Management4. EMI/EMC Considerations5. Simulation and Modeling1. Consumer Electronics2. Telecommunications3. Industrial Applications4. Renewable Energy Systems5. Medical Devices Success Stories ConclusionThe application development in switching converters and SMPS transformers, exemplified by the CFR-25JB-52-1R5, is driven by continuous advancements in magnetic design, control techniques, thermal management, EMI considerations, and simulation tools. The success stories across various industries underscore the versatility and efficiency of these technologies, highlighting their essential role in modern electronic systems. As the demand for more efficient and compact power solutions grows, ongoing innovations in this field are expected to further enhance performance and reliability, paving the way for new applications and markets.

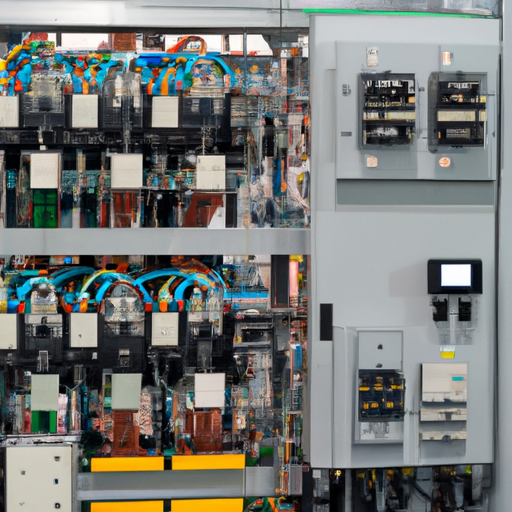

Overview of Isolation Transformers and AutotransformersIsolation transformers and autotransformers are pivotal components in electrical systems, serving essential functions in power distribution, voltage regulation, and safety. Below, we delve into the core functional technologies, applications, and notable development cases for both types of transformers, particularly focusing on step-up and step-down configurations.

Core Functional Technologies 1. Isolation Transformers

- **Functionality**: Isolation transformers transfer electrical energy between two circuits while providing electrical isolation. This isolation enhances safety by preventing electrical shocks and reducing the risk of equipment damage.

- **Construction**: Comprising two windings (primary and secondary) that are magnetically coupled but electrically isolated, isolation transformers can have a turns ratio of 1:1 or be designed for step-up or step-down applications.

- **Applications**: Commonly found in medical equipment, audio systems, and sensitive electronic devices, they protect against electrical noise and surges. 2. Autotransformers

- **Functionality**: Autotransformers utilize a single winding that serves as both the primary and secondary winding, allowing for variable voltage output. They are more compact and efficient than isolation transformers for specific applications.

- **Construction**: The winding is tapped at various points to provide different voltage levels, enabling step-up or step-down transformations.

- **Applications**: Frequently used in motor starting, voltage regulation in power distribution, and scenarios where space and efficiency are critical. Application Development Cases 1. Medical Equipment

- **Isolation Transformers**: In healthcare settings, isolation transformers power sensitive medical devices, ensuring patient safety and minimizing electromagnetic interference (EMI).

- **Case Study**: A hospital integrated isolation transformers into their MRI machines, enhancing patient safety and improving image quality by reducing noise. 2. Industrial Automation

- **Autotransformers**: In manufacturing, autotransformers step down voltage for machinery operating at lower voltages, saving energy and reducing transformer size and cost.

- **Case Study**: An automotive manufacturer employed autotransformers to manage voltage supply to robotic arms, achieving a 20% reduction in energy consumption and improved operational efficiency. 3. Renewable Energy Systems

- **Isolation Transformers**: In solar power systems, isolation transformers connect inverters to the grid, providing safety and preventing ground faults.

- **Case Study**: A solar farm integrated isolation transformers to ensure safe operation and compliance with grid standards, facilitating seamless energy transfer and enhancing system reliability. 4. Telecommunications

- **Isolation Transformers**: Used in telecom equipment to isolate sensitive circuits from power lines, preventing surges and ensuring reliable communication.

- **Case Study**: A telecom provider implemented isolation transformers in their data centers to protect servers from power fluctuations, resulting in reduced downtime and maintenance costs. 5. Power Distribution

- **Autotransformers**: In urban power distribution networks, autotransformers manage voltage levels across different grid sections, allowing for efficient energy distribution.

- **Case Study**: A city utility company upgraded its distribution network with autotransformers, improving voltage stability and reducing transmission losses by 15%. ConclusionIsolation transformers and autotransformers are integral to various applications, enhancing safety in medical devices, improving efficiency in industrial automation, and supporting renewable energy systems. Their capability to step up or step down voltage while providing isolation or efficiency makes them invaluable in modern electrical engineering. As technology advances, the development of these transformers continues to evolve, leading to more effective and innovative applications across multiple industries. The ongoing research and development in transformer technology promise to yield even more efficient designs and applications, further solidifying their role in the future of electrical systems.

Application Development in Pulse Transformers for CFR-50JB-52-1M5: Key Technologies and Success StoriesPulse transformers are essential components in various high-frequency applications, including power electronics, telecommunications, and signal processing. The CFR-50JB-52-1M5 model exemplifies a pulse transformer designed for efficient energy transfer and high-frequency operation. Below is an overview of the key technologies and notable success stories associated with the development and application of pulse transformers, particularly focusing on the CFR-50JB-52-1M5.

Key Technologies in Pulse Transformers1. High-Frequency Operation 2. Magnetic Core Materials 3. Winding Techniques 4. Thermal Management 5. Simulation and Modeling 6. Integration with Power Electronics 1. Telecommunications 2. Switching Power Supplies 3. Medical Devices 4. Industrial Automation 5. Renewable Energy Systems Success Stories ConclusionThe development and application of pulse transformers like the CFR-50JB-52-1M5 are driven by advancements in materials, design techniques, and integration with modern electronics. The success stories across various industries underscore their versatility and importance in achieving efficient, reliable, and high-performance systems. As technology continues to evolve, pulse transformers are poised to play an even more significant role in emerging applications, particularly in renewable energy, telecommunications, and advanced power electronics. The ongoing innovation in this field will likely lead to new applications and improved performance characteristics, further solidifying the importance of pulse transformers in modern technology.

CFR-25JB-52-1K5 Specialty Transformers: Core Functional Technology and Application DevelopmentIntroduction to Specialty Transformers

Specialty transformers, such as the CFR-25JB-52-1K5, are engineered for specific applications that demand unique electrical characteristics, performance standards, and operational capabilities. These transformers are vital across various sectors, including telecommunications, renewable energy, medical equipment, and industrial automation, where standard transformers may not suffice. Core Functional Technology1. High Efficiency and Low Losses2. Customizable Voltage and Current Ratings3. Thermal Management4. Compact Design5. Isolation and Safety Features1. Telecommunications2. Renewable Energy Systems3. Medical Equipment4. Industrial Automation5. Electric Vehicle Charging Stations Application Development Cases ConclusionThe CFR-25JB-52-1K5 specialty transformer represents significant advancements in transformer technology, offering high efficiency, customizable features, and robust performance across diverse applications. Its versatility makes it an essential component in modern electrical systems, contributing to innovative solutions in telecommunications, renewable energy, medical technology, industrial automation, and electric vehicle infrastructure. As industries continue to evolve, specialty transformers will play a crucial role in meeting the demands of new technologies and applications, ensuring reliability and efficiency in an increasingly electrified world.

Application Development in Power Transformers for CFR-50JB-52-1K5: Key Technologies and Success StoriesDeveloping applications for power transformers, such as the CFR-50JB-52-1K5, involves leveraging various key technologies and methodologies to enhance performance, reliability, and efficiency. Below are some key technologies and success stories related to application development in power transformers.

Key Technologies1. Smart Grid Integration2. Advanced Materials3. Digital Twin Technology4. Condition Monitoring Systems5. Energy Management Systems (EMS)6. Renewable Energy Integration1. Predictive Maintenance Implementation2. Smart Transformer Deployment3. Renewable Integration Project4. Digital Twin for Optimization5. Nanocrystalline Core Development Success Stories ConclusionThe application development for power transformers like the CFR-50JB-52-1K5 is rapidly evolving with advancements in technology. By leveraging IoT, advanced materials, digital twins, and smart grid integration, companies can significantly enhance the performance and reliability of transformers. The success stories illustrate the transformative potential of these technologies in the power industry, addressing the growing demands for energy efficiency and sustainability. As the industry continues to innovate, the future of power transformers looks promising, with opportunities for further enhancements in efficiency, reliability, and integration with renewable energy sources.

Application Development in Audio Transformers for LT1213CS8: Key Technologies and Success StoriesDeveloping applications for audio transformers, particularly the LT1213CS8, involves leveraging a variety of technologies and methodologies to enhance audio performance, fidelity, and reliability. The LT1213CS8 is a high-performance audio transformer designed for low-noise applications, making it suitable for a range of audio processing tasks. Below are key technologies and notable success stories related to application development in this area.

Key Technologies1. Analog Signal Processing2. Digital Signal Processing (DSP)3. High-Fidelity Components4. PCB Design and Layout5. Software Development6. Testing and Validation1. Professional Audio Equipment2. Live Sound Reinforcement3. Home Audio Systems4. Broadcasting5. Musical Instrument Amplifiers Success Stories ConclusionThe development of applications using audio transformers like the LT1213CS8 is a multifaceted endeavor that combines analog and digital technologies, high-quality components, and innovative design practices. Success stories across various sectors, including professional audio, live sound, home audio, broadcasting, and musical instruments, highlight the transformative impact of these technologies on audio performance. As the demand for high-quality audio continues to grow, the integration of advanced audio transformers will remain a key focus for developers and manufacturers in the industry. The LT1213CS8 stands out as a pivotal component in achieving superior audio fidelity and reliability across diverse applications.

Overview of Trimmer Potentiometers: CFR-50JB-52-1K3Trimmer potentiometers, such as the CFR-50JB-52-1K3, are essential components in electronic design, providing adjustable resistance for fine-tuning circuit parameters. Their versatility and reliability make them invaluable in a variety of applications, from consumer electronics to industrial systems. Below, we delve into the core functional technologies and application development cases that showcase the effectiveness of trimmer potentiometers.

Core Functional Technologies1. Adjustable Resistance 2. Compact Design 3. Durability and Reliability 4. Temperature Stability 5. Low Noise Operation 1. Audio Equipment Calibration 2. Sensor Calibration 3. Power Supply Regulation 4. Feedback Control Systems 5. Consumer Electronics 6. Test Equipment Application Development Cases ConclusionTrimmer potentiometers, exemplified by the CFR-50JB-52-1K3, are integral to modern electronic design, providing essential adjustable resistance for calibration and fine-tuning across a multitude of applications. Their compact design, durability, and low noise operation make them suitable for diverse uses, from audio equipment to precision measurement devices. As technology advances, the role of trimmer potentiometers in optimizing electronic circuit performance remains crucial, underscoring their importance in the ever-evolving landscape of electronics.